-

Blast Equipment

High performance abrasive blasting equipment engineered to be incredibly tough, safe and durable.

-

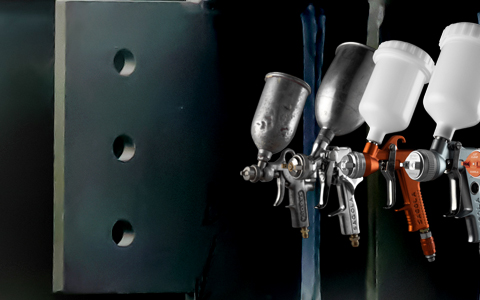

Spray Equipment

Engineered for the most demanding automotive bodyshops, wood & fine finish spray booths, industrial finishing, automated paint lines and protective coatings.

-

Coatings Inspection

The coating process requires inspection at every stage to ensure compliance to the specification.

-

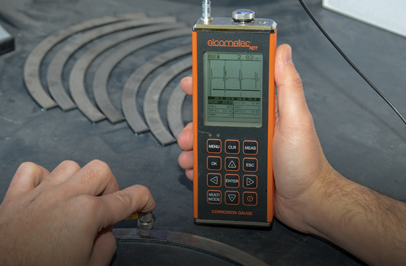

NDT Equipment

Ultrasonic thickness gauges are used to accurately determine the thickness of a variety of materials.

-

Concrete Inspection

Whether you are trying to determine a rebar’s location, depth, diameter and orientation or its potential for corrosion using half-cell, the Elcometer range of concrete inspection equipment is required.

-

About Elcometer

Discover More

Welcome to elcometer.tv

Your ultimate training channel

Software Download

Download Elcometer's FREE data management

software for professional reports in seconds