Elcometer 5100 Payne Permeability Cup

- Industrial Finishing

- Paint Manufacture

- Laboratory & Physical Test

The Elcometer 5100 Payne Permeability Cups are made of anodised aluminium and are used to determine the permeability of films of paints, varnish, plastic, cellophane, etc.

- Summary

-

Summary

-

The water evaporates or is absorbed by the cups and, after a certain time, the weight change relative to the film thickness is calculated, indicating the degree of permeability or permeance.

-

- Key Features

-

Key Features

Elcometer 5100 Payne Permeability Cup

How to use Payne Permeability Cups

Prepare the film to be tested using a film applicator and suitable test chart.

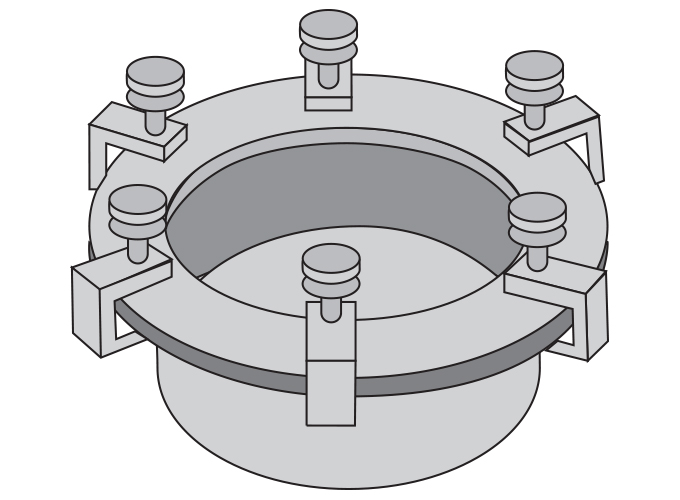

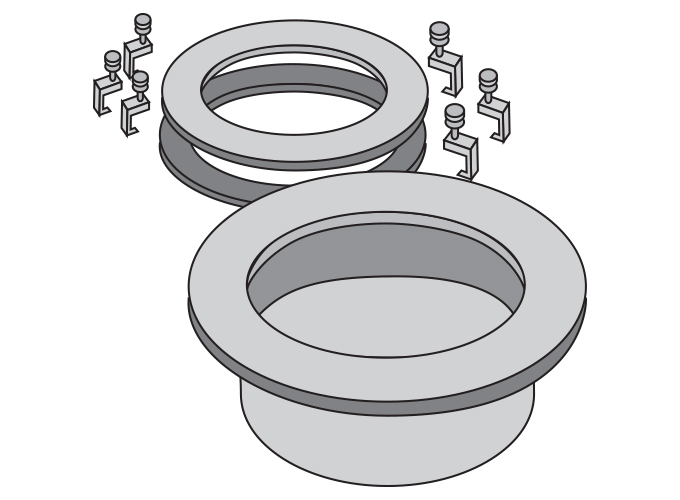

Prepare the film to be tested using a film applicator and suitable test chart. Disassemble the permeability cup.

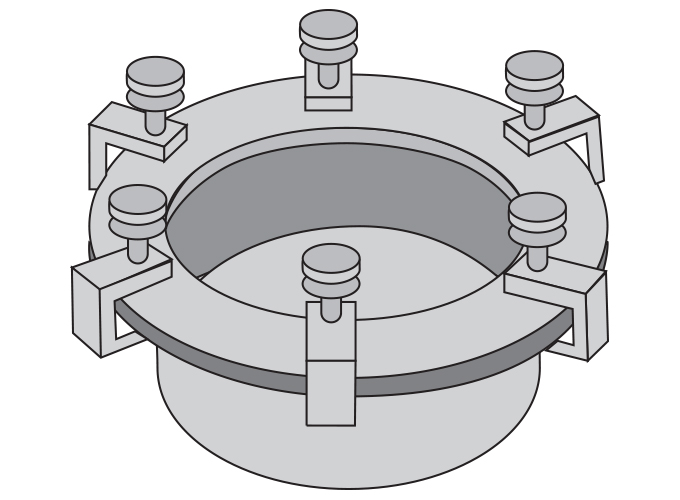

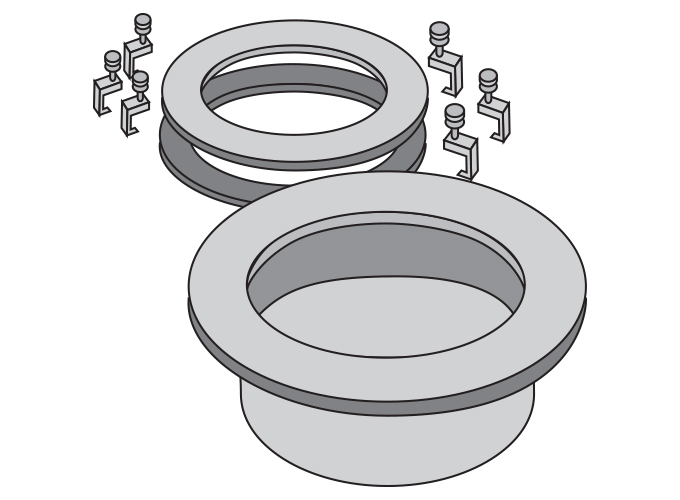

Disassemble the permeability cup.

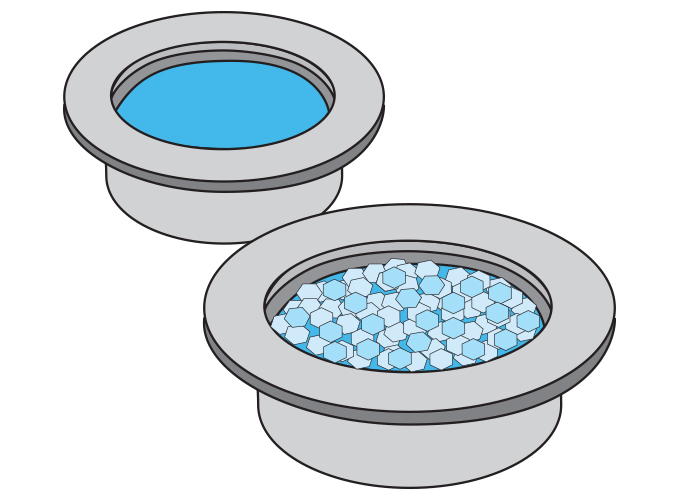

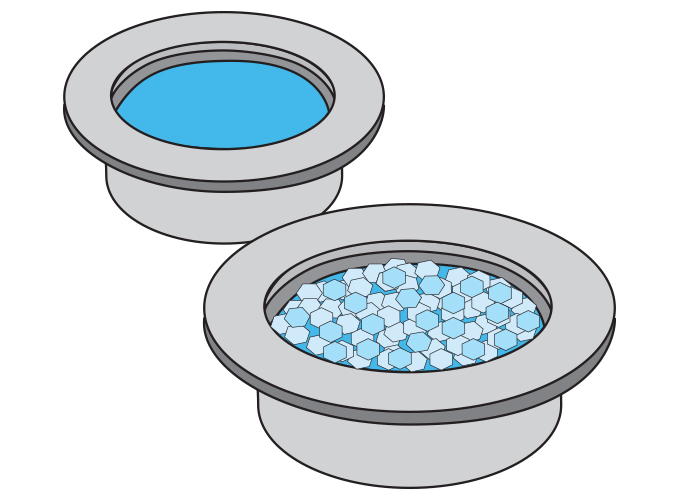

Fill with required liquid (typically water) or dry desiccant (absorbent). Place the film on to the cup and reassemble making sure the gasket is fitted.

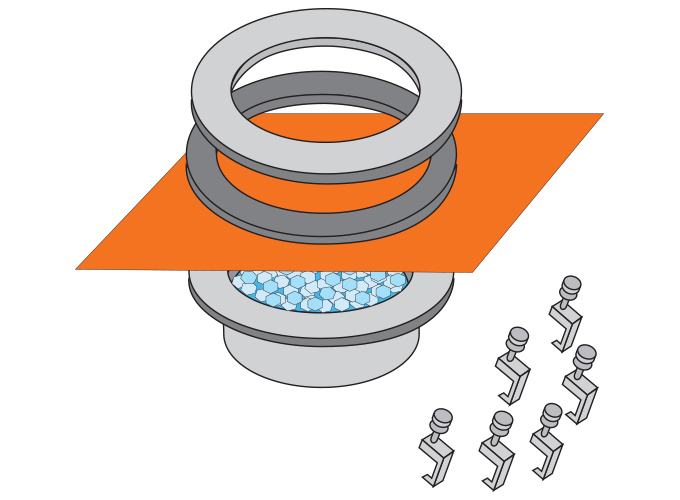

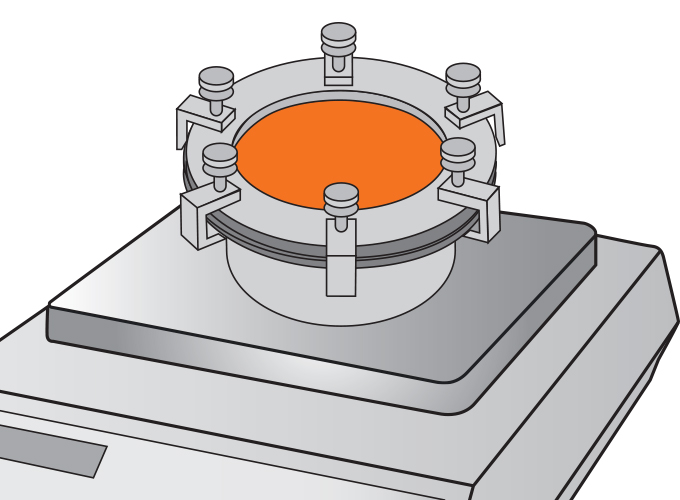

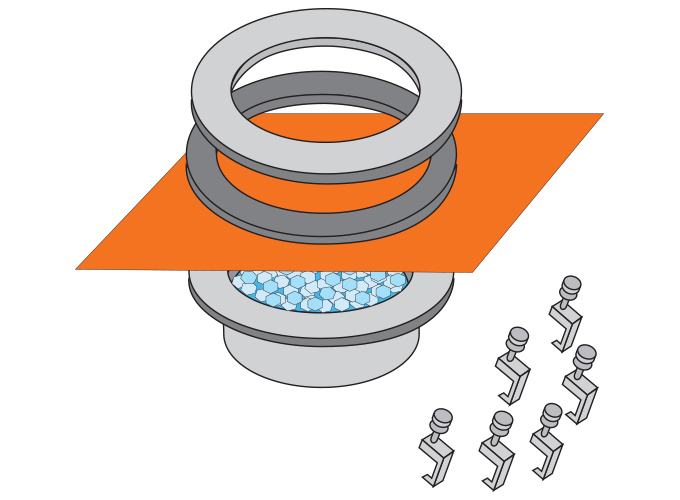

Place the film on to the cup and reassemble making sure the gasket is fitted. Weigh the prepared permeability cup and record the result (in grams).

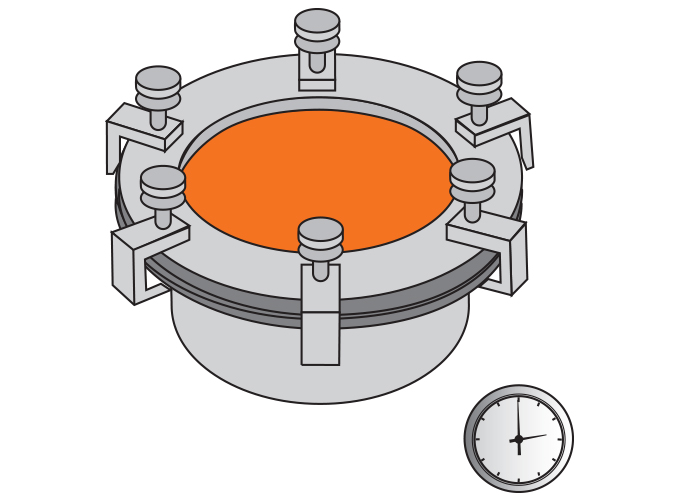

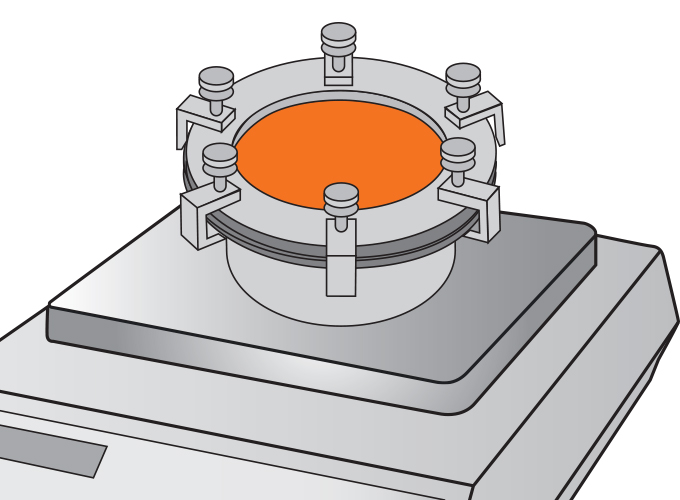

Weigh the prepared permeability cup and record the result (in grams). Leave for appropriate time, re-weigh, calculate the change in mass (∆m) & water vapour transmission rate.

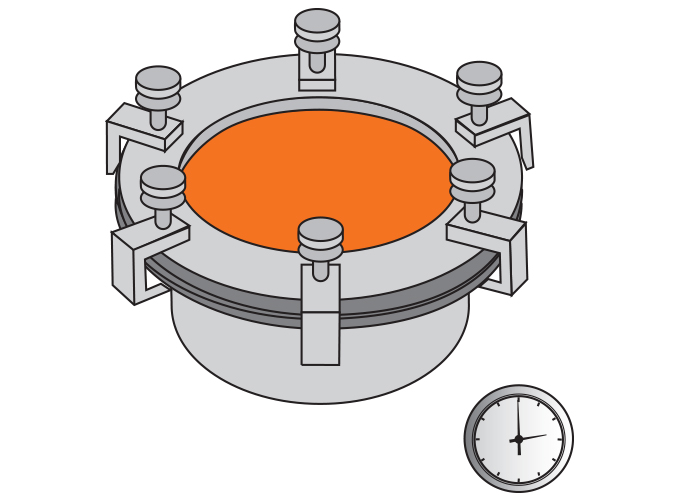

Leave for appropriate time, re-weigh, calculate the change in mass (∆m) & water vapour transmission rate.

-

- Technical Information

-

Technical SpecificationElcometer 5100 Payne Permeability Cup

Part Number Description Area Volume cm2 inches2 cm3 inches3 K0005100M201 Elcometer 5100/1 Payne Permeability Cup 10 1.55 15 0.91 K0005100M202 Elcometer 5100/2 Payne Permeability Cup 30 4.65 50 3.05 K0005100M203 Elcometer 5100/3 Payne Permeability Cup 30 4.65 75 4.58 Packing List Elcometer 5100 Payne Permeability Cup, storage case and operating instructions Part Number Description K0005100M201 Elcometer 5100/1 Payne Permeability Cup Area cm2 inches2 10 1.55 Volume cm3 inches3 15 0.91 Part Number Description K0005100M202 Elcometer 5100/2 Payne Permeability Cup Area cm2 inches2 30 4.65 Volume cm3 inches3 50 3.05 Part Number Description K0005100M203 Elcometer 5100/3 Payne Permeability Cup Area cm2 inches2 30 4.65 Volume cm3 inches3 75 4.58 Packing List Elcometer 5100 Payne Permeability Cup, storage case and operating instructions

-

- Standards

-

StandardsElcometer 5100 Payne Permeability Cup

ASTM D1653, ASTM E96, ISO 7783-1, ISO 7783-2

-

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersElcometer 5100 Payne Permeability CupNo data found!!

-

Elcometer 5100/1 Payne Permeability Cup

Elcometer 5100/1 Payne Permeability Cup- Part Number : K0005100M201

-

Elcometer 5100/2 Payne Permeability Cup

Elcometer 5100/2 Payne Permeability Cup- Part Number : K0005100M202

-

Elcometer 5100/3 Payne Permeability Cup

Elcometer 5100/3 Payne Permeability Cup- Part Number : K0005100M203

- Accessories

-

AccessoriesElcometer 5100 Payne Permeability Cup

Part Number: K0004695M112

Part Number: K0004695M112

-

- Home

- Coatings Inspection

- Coatings Inspection Division

- Drying Time & Permeability

- Elcometer 5100 Payne Permeability Cup

Elcometer 5100 Payne Permeability Cup

- Industrial Finishing

- Paint Manufacture

- Laboratory & Physical Test

The Elcometer 5100 Payne Permeability Cups are made of anodised aluminium and are used to determine the permeability of films of paints, varnish, plastic, cellophane, etc.

Summary

Elcometer 5100 Payne Permeability Cup

The water evaporates or is absorbed by the cups and, after a certain time, the weight change relative to the film thickness is calculated, indicating the degree of permeability or permeance.

Key Features

Elcometer 5100 Payne Permeability Cup

How to use Payne Permeability Cups

Prepare the film to be tested using a film applicator and suitable test chart.

Prepare the film to be tested using a film applicator and suitable test chart. Disassemble the permeability cup.

Disassemble the permeability cup.

Fill with required liquid (typically water) or dry desiccant (absorbent). Place the film on to the cup and reassemble making sure the gasket is fitted.

Place the film on to the cup and reassemble making sure the gasket is fitted. Weigh the prepared permeability cup and record the result (in grams).

Weigh the prepared permeability cup and record the result (in grams). Leave for appropriate time, re-weigh, calculate the change in mass (∆m) & water vapour transmission rate.Technical SpecificationElcometer 5100 Payne Permeability Cup

Leave for appropriate time, re-weigh, calculate the change in mass (∆m) & water vapour transmission rate.Technical SpecificationElcometer 5100 Payne Permeability CupPart Number Description Area Volume cm2 inches2 cm3 inches3 K0005100M201 Elcometer 5100/1 Payne Permeability Cup 10 1.55 15 0.91 K0005100M202 Elcometer 5100/2 Payne Permeability Cup 30 4.65 50 3.05 K0005100M203 Elcometer 5100/3 Payne Permeability Cup 30 4.65 75 4.58 Packing List Elcometer 5100 Payne Permeability Cup, storage case and operating instructions Part Number Description K0005100M201 Elcometer 5100/1 Payne Permeability Cup Area cm2 inches2 10 1.55 Volume cm3 inches3 15 0.91 Part Number Description K0005100M202 Elcometer 5100/2 Payne Permeability Cup Area cm2 inches2 30 4.65 Volume cm3 inches3 50 3.05 Part Number Description K0005100M203 Elcometer 5100/3 Payne Permeability Cup Area cm2 inches2 30 4.65 Volume cm3 inches3 75 4.58 Packing List Elcometer 5100 Payne Permeability Cup, storage case and operating instructions Part NumbersElcometer 5100 Payne Permeability CupNo data found!!-

Elcometer 5100/1 Payne Permeability Cup

Elcometer 5100/1 Payne Permeability Cup- Part Number : K0005100M201

-

Elcometer 5100/2 Payne Permeability Cup

Elcometer 5100/2 Payne Permeability Cup- Part Number : K0005100M202

-

Elcometer 5100/3 Payne Permeability Cup

Elcometer 5100/3 Payne Permeability Cup- Part Number : K0005100M203

AccessoriesElcometer 5100 Payne Permeability Cup Part Number: K0004695M112

Part Number: K0004695M112

- Part Numbers

-