Elcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

The Elcometer 121/4 Paint Inspection Gauge (P.I.G) is a hand-held paint gauge that offers a quick, versatile method of coating examination and measurement in a portable, easy-to-use format.

- Summary

-

Summary

-

The paint inspection gauge is available in two versions, Standard and Top:

Standard paint gauges can be used for microscopic coating examination and destructive measurement of coating thickness.

Top inspection gauges have the same functionality as standard paint gauges and can also be used for cross hatch adhesion testing using optional tools.

Key Features

- Compact and convenient, ideal for paint thickness measurement in confined areas

- Made of anodised aluminium for durability

- Built-in 50x micropscope with rotatable graticule scale

- Bright white LED light source for clear vision through the microscope

- The standard paint inspection gauge holds a single cutting tool with built-in storage for 3 cutting tools

- The top model paint gauge cutting tools are mounted on a rotary tool holder within the body of the gauge, allowing rapid change from one test to the next

- The top model tool holder accommodates three cutting tools plus an optional cross hatch cutting tool

-

- Key Features

-

Key Features

Elcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

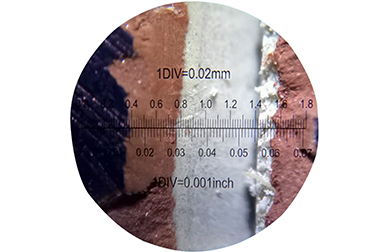

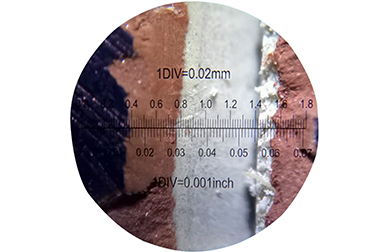

Assessing your results using the Elcometer 121/4 Paint Inspection Gauge

Destructive dry film thickness test

Position the gauge vertically so that the microscope lens is over the cut.

Look through the microscope lens and rotate the focus adjuster until the cut is visible clearly.

-

- Technical Information

-

Technical SpecificationElcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

Description Elcometer 121/4 Standard Paint Inspection Gauge Elcometer 121/4 Top Paint Inspection Gauge Certificate Part Number A121---S A121---T

Range 2 - 2,000μm (0.08 - 80mils) Accuracy is dependent on tool cut angle, half a division Weight Standard: 369g (13oz)

Top: 383g (13.5oz)Dimensions Standard: 110 x 75 x 30mm (4.3 x 3 x 1.2”)

Top: 110 x 75 x 40mm (4.3 x 3 x 1.6")Packing List Elcometer 121/4, cutters 1, 4 and 6, microscope (x50 magnification), 4 x AG3 batteries for lamp (fitted), hexagonal wrench, black marker pen, wrist strap, carry case and operating instructions Part Number A121---S A121---T Certificate

Description Elcometer 121/4 Standard Paint Inspection Gauge Elcometer 121/4 Top Paint Inspection Gauge Range 2 - 2,000μm (0.08 - 80mils) Accuracy is dependent on tool cut angle, half a division Weight Standard: 369g (13oz)

Top: 383g (13.5oz)Dimensions Standard: 110 x 75 x 30mm (4.3 x 3 x 1.2”)

Top: 110 x 75 x 40mm (4.3 x 3 x 1.6")Packing List Elcometer 121/4, cutters 1, 4 and 6, microscope (x50 magnification), 4 x AG3 batteries for lamp (fitted), hexagonal wrench, black marker pen, wrist strap, carry case and operating instructions ○ Optional Calibration Certificate available

-

- Standards

-

StandardsElcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

AS 1580.108.2, AS 1580.408.4*, AS 3894.9*, ASTM D 3359-B*, ASTM D 4138-A, BS 3900-C5-5B, BS 3900-E6*, DIN 50986, ECCA T6*, EN 13523-6*, ISO 2808-5B, ISO 16276-2*, ISO 2409*, ISO 2808-6B, JIS K 5600-1-7, NF T30-038*, NF T30-123

* Standards apply to Top Model only

Standards in grey have been superseded but are still recognised in some industries.

-

- Downloads

-

Downloads

- Part Numbers

-

Part NumbersElcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)No data found!!

-

Elcometer 121/4 Standard Paint Inspection Gauge

Elcometer 121/4 Standard Paint Inspection Gauge- Part Number : A121---S

-

Elcometer 121/4 Standard Paint Inspection Gauge

Elcometer 121/4 Standard Paint Inspection Gauge- Part Number : A121---SC

-

Elcometer 121/4 Top Paint Inspection Gauge

Elcometer 121/4 Top Paint Inspection Gauge- Part Number : A121---T

-

Elcometer 121/4 Top Paint Inspection Gauge

Elcometer 121/4 Top Paint Inspection Gauge- Part Number : A121---TC

- Accessories

-

AccessoriesElcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

Part Number: T99915761-1

Part Number: T99915761-1 Part Number: T99915761-4

Part Number: T99915761-4 Part Number: T99915761-6

Part Number: T99915761-6 Part Number: T99913700-1

Part Number: T99913700-1 Part Number: T99913700-2

Part Number: T99913700-2 Part Number: T99913700-3

Part Number: T99913700-3 Part Number: T99913700-4

Part Number: T99913700-4 Part Number: T99913700-5

Part Number: T99913700-5 Part Number: K0001539M001

Part Number: K0001539M001 Part Number: T9998894-

Part Number: T9998894- Part Number: T9999358-1

Part Number: T9999358-1 Part Number: T9999358-2

Part Number: T9999358-2

-

- Home

- Coatings Inspection

- Coatings Inspection Division

- Dry Film Thickness

- Destructive Coating Thickness Gauges

- Elcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

Elcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

The Elcometer 121/4 Paint Inspection Gauge (P.I.G) is a hand-held paint gauge that offers a quick, versatile method of coating examination and measurement in a portable, easy-to-use format.

Summary

Elcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

The paint inspection gauge is available in two versions, Standard and Top:

Standard paint gauges can be used for microscopic coating examination and destructive measurement of coating thickness.

Top inspection gauges have the same functionality as standard paint gauges and can also be used for cross hatch adhesion testing using optional tools.

Key Features

- Compact and convenient, ideal for paint thickness measurement in confined areas

- Made of anodised aluminium for durability

- Built-in 50x micropscope with rotatable graticule scale

- Bright white LED light source for clear vision through the microscope

- The standard paint inspection gauge holds a single cutting tool with built-in storage for 3 cutting tools

- The top model paint gauge cutting tools are mounted on a rotary tool holder within the body of the gauge, allowing rapid change from one test to the next

- The top model tool holder accommodates three cutting tools plus an optional cross hatch cutting tool

Key Features

Elcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)

Assessing your results using the Elcometer 121/4 Paint Inspection Gauge

Destructive dry film thickness test

Position the gauge vertically so that the microscope lens is over the cut.

Look through the microscope lens and rotate the focus adjuster until the cut is visible clearly.

Technical SpecificationElcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)Description Elcometer 121/4 Standard Paint Inspection Gauge Elcometer 121/4 Top Paint Inspection Gauge Certificate Part Number A121---S A121---T

Range 2 - 2,000μm (0.08 - 80mils) Accuracy is dependent on tool cut angle, half a division Weight Standard: 369g (13oz)

Top: 383g (13.5oz)Dimensions Standard: 110 x 75 x 30mm (4.3 x 3 x 1.2”)

Top: 110 x 75 x 40mm (4.3 x 3 x 1.6")Packing List Elcometer 121/4, cutters 1, 4 and 6, microscope (x50 magnification), 4 x AG3 batteries for lamp (fitted), hexagonal wrench, black marker pen, wrist strap, carry case and operating instructions Part Number A121---S A121---T Certificate

Description Elcometer 121/4 Standard Paint Inspection Gauge Elcometer 121/4 Top Paint Inspection Gauge Range 2 - 2,000μm (0.08 - 80mils) Accuracy is dependent on tool cut angle, half a division Weight Standard: 369g (13oz)

Top: 383g (13.5oz)Dimensions Standard: 110 x 75 x 30mm (4.3 x 3 x 1.2”)

Top: 110 x 75 x 40mm (4.3 x 3 x 1.6")Packing List Elcometer 121/4, cutters 1, 4 and 6, microscope (x50 magnification), 4 x AG3 batteries for lamp (fitted), hexagonal wrench, black marker pen, wrist strap, carry case and operating instructions ○ Optional Calibration Certificate availableStandardsElcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)AS 1580.108.2, AS 1580.408.4*, AS 3894.9*, ASTM D 3359-B*, ASTM D 4138-A, BS 3900-C5-5B, BS 3900-E6*, DIN 50986, ECCA T6*, EN 13523-6*, ISO 2808-5B, ISO 16276-2*, ISO 2409*, ISO 2808-6B, JIS K 5600-1-7, NF T30-038*, NF T30-123

* Standards apply to Top Model only

Standards in grey have been superseded but are still recognised in some industries.

Part NumbersElcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.)No data found!!-

Elcometer 121/4 Standard Paint Inspection Gauge

Elcometer 121/4 Standard Paint Inspection Gauge- Part Number : A121---S

-

Elcometer 121/4 Standard Paint Inspection Gauge

Elcometer 121/4 Standard Paint Inspection Gauge- Part Number : A121---SC

-

Elcometer 121/4 Top Paint Inspection Gauge

Elcometer 121/4 Top Paint Inspection Gauge- Part Number : A121---T

-

Elcometer 121/4 Top Paint Inspection Gauge

Elcometer 121/4 Top Paint Inspection Gauge- Part Number : A121---TC

AccessoriesElcometer 121/4 Standard & Top Paint Inspection Gauges (P.I.G.) Part Number: T99915761-1

Part Number: T99915761-1 Part Number: T99915761-4

Part Number: T99915761-4 Part Number: T99915761-6

Part Number: T99915761-6 Part Number: T99913700-1

Part Number: T99913700-1 Part Number: T99913700-2

Part Number: T99913700-2 Part Number: T99913700-3

Part Number: T99913700-3 Part Number: T99913700-4

Part Number: T99913700-4 Part Number: T99913700-5

Part Number: T99913700-5 Part Number: K0001539M001

Part Number: K0001539M001 Part Number: T9998894-

Part Number: T9998894- Part Number: T9999358-1

Part Number: T9999358-1 Part Number: T9999358-2

Part Number: T9999358-2

- Part Numbers

-