Elcometer 510 Automatic Pull-Off Adhesion Gauge

- Protective Coatings

- Industrial Finishing

The Elcometer 510 Automatic Pull-Off Adhesion Gauge accurately measures the adhesion strength of coatings on a wide range of substrates.

- Summary

-

Summary

-

Accurate Pull-Off Measurements

- Fully adjustable pull rates 0.1-1.4MPa/s (14.5-203psi)

- Accuracy of ±1% of full scale

- Can be used in accordance with National & International Standards

- Interchangeable units: MPa, psi, Nmm² and N

Powerful Adhesion Tester

- Smooth load application up to 100MPa (14,400psi)

- USB and Bluetooth® data output to iOS or Android™ devices

- Stores up to 60,000 readings in 2,500 batches

Efficient Adhesion Testing

- Ideal for laboratory and field use

- 10, 14.2, 20 & 50mm (0.39, 0.56, 0.76 & 1.96”) diameter reusable dollies

- Compatible with ElcoMaster® Software

- Range of substrate actuator skirts for thick, thin, flat or convex substrates

Using an automatic hydraulic pump, the Elcometer 510 Pull-Off Adhesion Tester ensures smooth and continuous pressure application for consistent and repeatable results. Whilst the rate of pull is controlled manually for most pull-off adhesion testers, the Elcometer 510 Pull-Off Adhesion Gauge allows the rate of pull to be selected, and the gauge applies the pre-selected rate automatically.

The Elcometer 510 Pull-Off Adhesion Tester includes all the features that you have come to expect from an Elcometer designed and manufactured product, including ease of use, robust and ergonomic design, menu driven colour display, user selectable statistics and display modes.

As well as reducing inspection times, the Elcometer 510 Pull-Off Adhesion Gauge can also speed up inspection reporting. When out in the field or on site, users can instantly review their data using Elcometer’s free data management software, ElcoMaster®. Each live reading can be transferred via Bluetooth® to a PC, or mobile devices and, at the click of a button, users are able to generate professional reports.

-

- Key Features

-

Key Features

Elcometer 510 Automatic Pull-Off Adhesion Gauge

Durability That Lasts

- Sealed, heavy duty and impact resistant

- Dust and waterproof equivalent to IP64

- Suitable for use in harsh environments

An Adhesion Gauge You Can Trust

- Repeatable and reproducible pull off measurements

- 2 year gauge warranty

- Batch date and time stamp facility

Adhesion Tests Made Simple

- Supplied in a robust plastic carry case for easy transportation

- USB and Bluetooth® data output to iPhone or Android™ devices

- Bright LCD colour screen

Elcometer 510 Automatic Pull-Off Adhesion Gauge Features Explained:

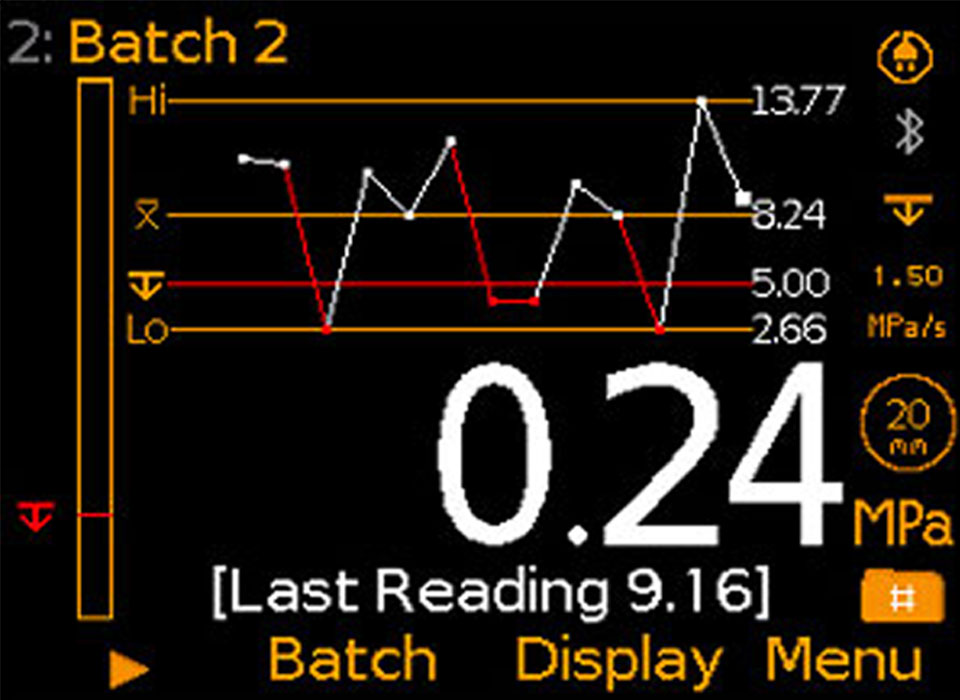

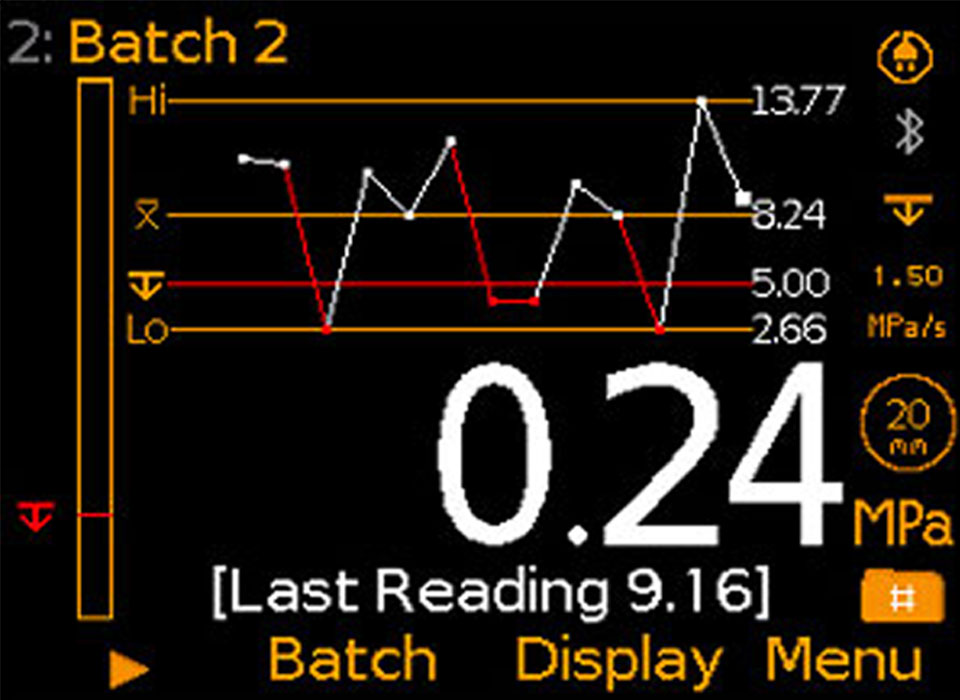

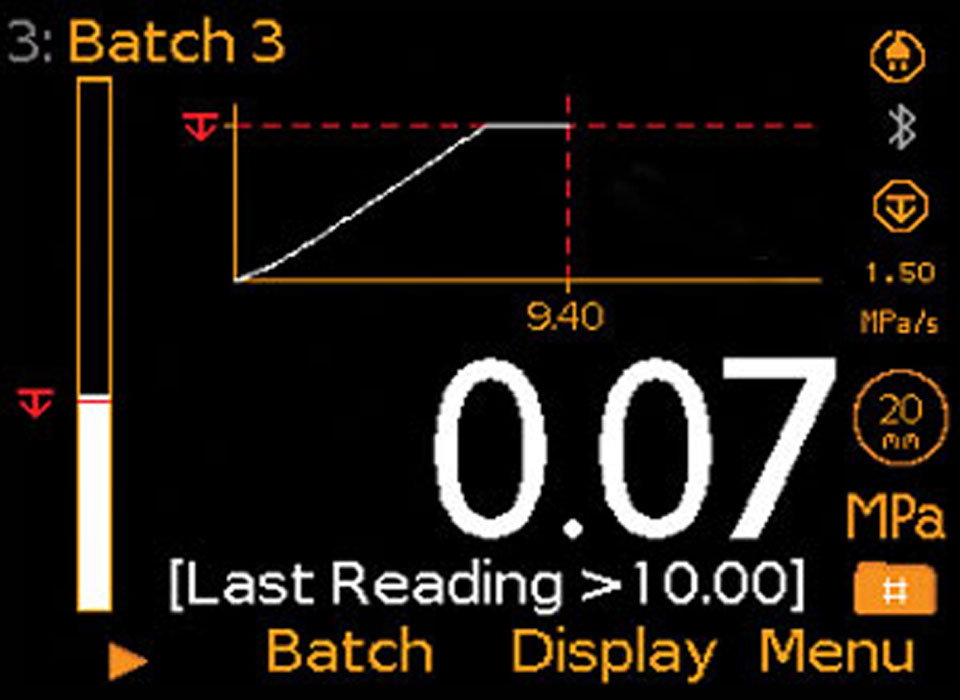

Automatic adhesion tester with selectable pull rates for 10, 14.2, 20 & 50mm diameter dollies. View adhesion trend graphs or live statistics alongside the reading value.

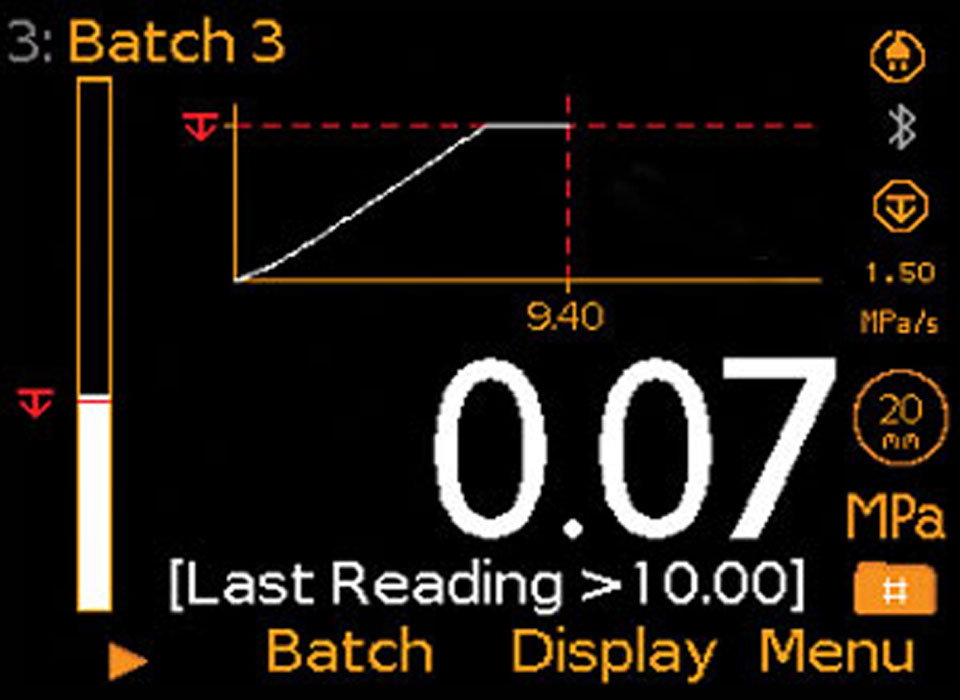

View adhesion trend graphs or live statistics alongside the reading value. Individual user-definable adhesion pull rate graphs can be saved with each reading.

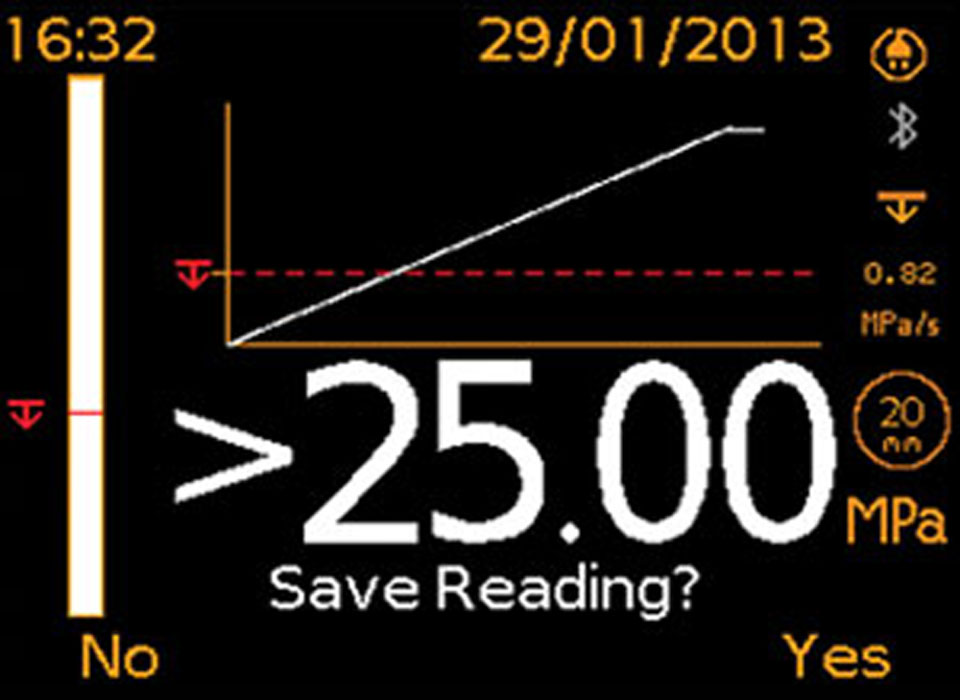

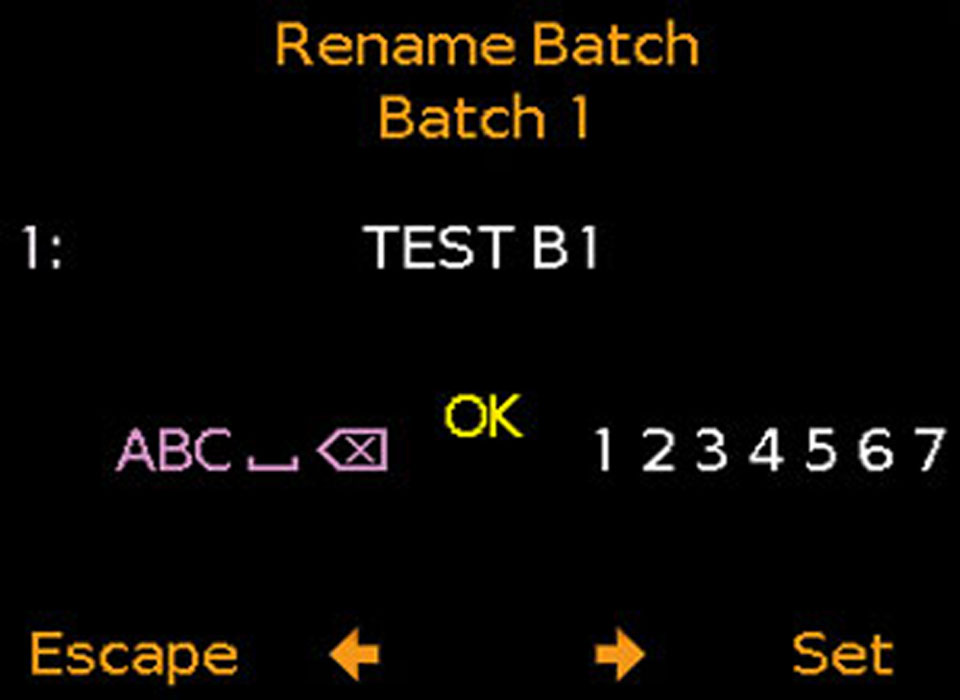

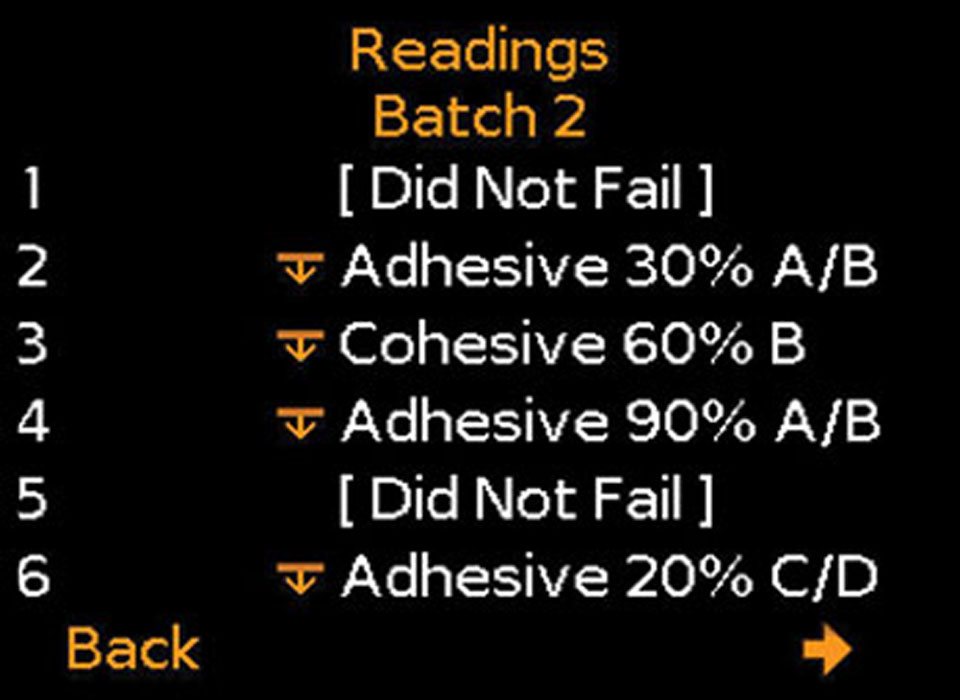

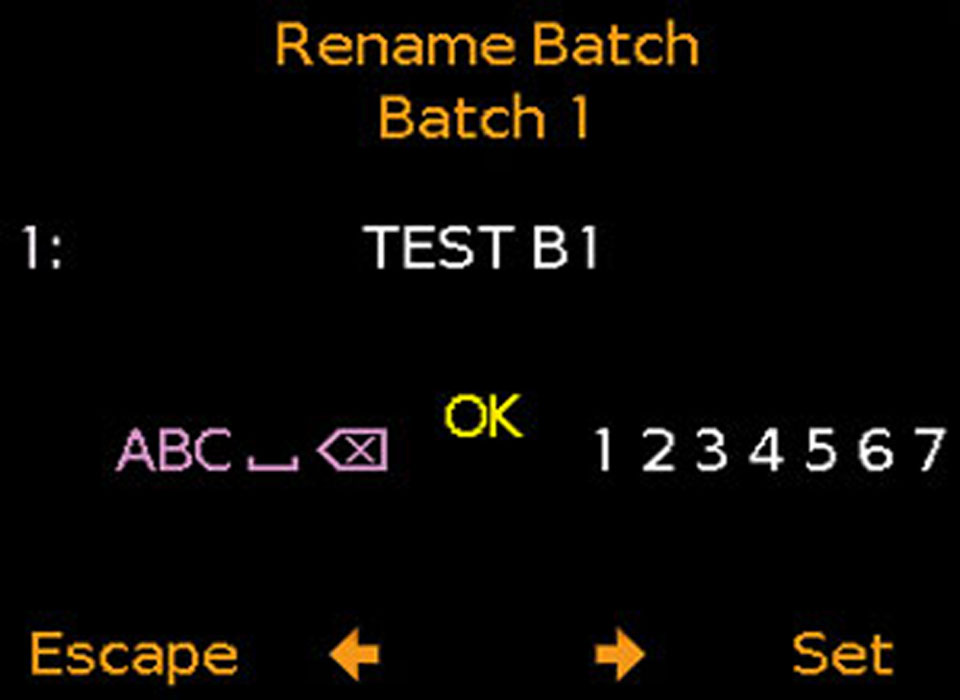

Individual user-definable adhesion pull rate graphs can be saved with each reading. Stores individual adhesion strength readings and pull rate graphs in up to 2,500 alpha numeric batches, together with date, time and attribute information.

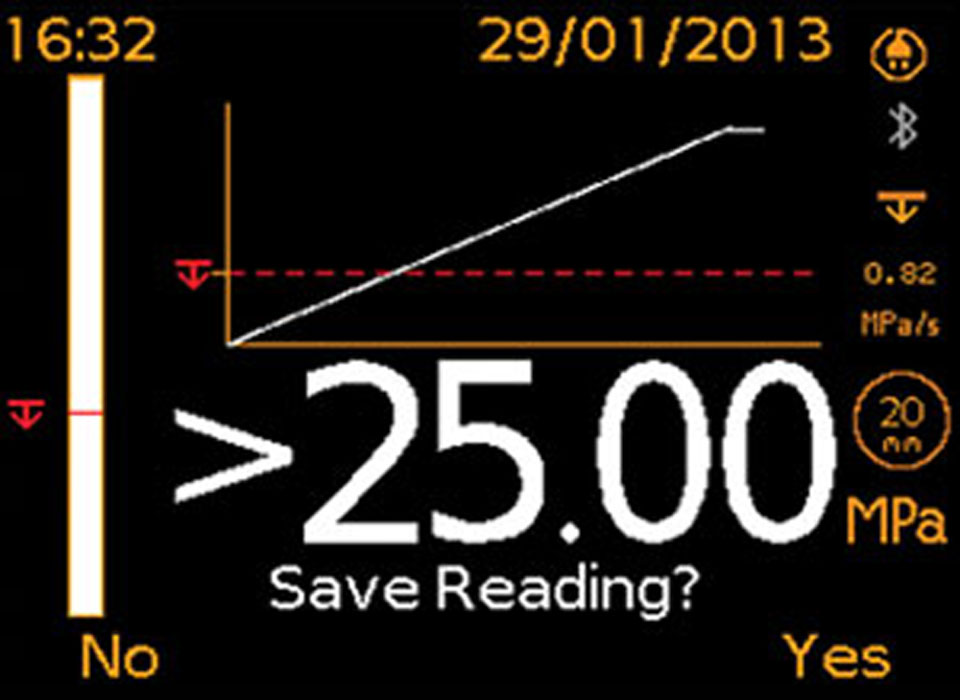

Stores individual adhesion strength readings and pull rate graphs in up to 2,500 alpha numeric batches, together with date, time and attribute information. Either pull to maximum or pull to preset limit. Unique time hold feature allows users to set a delay before pressure returns to zero.

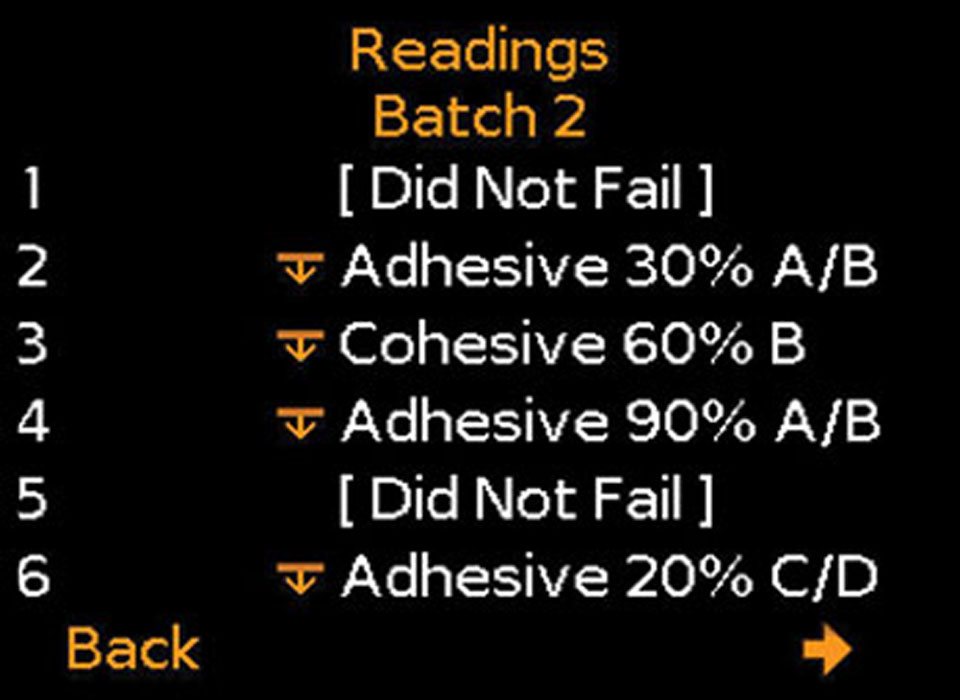

Either pull to maximum or pull to preset limit. Unique time hold feature allows users to set a delay before pressure returns to zero. Save cohesive and adhesive failure attributes alongside your adhesion pull data in accordance with National and International Standards.

Save cohesive and adhesive failure attributes alongside your adhesion pull data in accordance with National and International Standards.

-

- Product Features

-

Product FeaturesElcometer 510 Automatic Pull-Off Adhesion Gauge

Model S Model T Repeatable & reproducible measurements Easy to use menu structure in multiple languages Tough, impact, waterproof & dust resistant; equivalent to IP64 Bright LCD colour screen; with ambient light sensor Scratch & solvent resistant display; 2.4” (6cm) TFT Calibration certificate 2 year gauge warranty1 Automatic rotating display; 0°, 180° Data output via USB (Live readings - and batch) Data output via Bluetooth® PC command; start & stop gauge from a PC with live readings (USB only) Switchable Units (MPa, psi, N, Nmm-2) On Screen Statistics (η, x, σ, Hi, Lo, CV%, N>hi limit2) Pull Rate Indicator Trend Graph Pull Rate Graph (Load v Time) Interchangeable Dolly Selection; 10, 14.2, 20 & 50mm User Selectable Pull Rates; (Model S & Model T Standard Mode) 10mm: 1.00, 2.00, 3.00, 4.00, 5.00MPa/s 125, 200, 400, 600, 725psi/s 14.2mm: 0.4, 0.7, 1.4, 2.0, 2.5MPa/s 60, 100, 200, 300, 360psi/s 20mm: 0.2, 0.3, 0.7, 1.0, 1.2MPa/s 30, 50, 100, 150, 180psi/s 50mm: 0.04, 0.08, 0.12, 0.16, 0.20MPa/s 5, 8, 16, 24, 30psi/s User Selectable Pull Rates; (Model T Advanced Mode) 10mm: 0.40 - 5.60MPa/s 58 - 812psi/s in 0.1MPa / 1psi steps 14.2mm: 0.20 - 2.80MPa/s 29 - 403psi/s in 0.1MPa / 1psi steps 20mm: 0.10 - 1.40MPa/s 15 - 203psi/s in 0.1MPa / 1psi steps 50mm: 0.02 - 0.22MPa/s 2 - 32psi/s in 0.01MPa / 0.1psi steps User Selectable Limit & Limit Hold Time Gauge Memory; maximum number of readings 6060,0003Number of Batches (Alpha Numeric - Model T) 12,500Attribute Modes to meet National & International Standards Display Modes Readings, Selected Stats & Run Chart (last 20 readings) Pull Rate Graphs Batch Review Power; Battery (B), AC Mains Power (M) BB, MUSB Cable & ElcoMaster® Software CD Power Cable with Multi International Plug Adaptor (UK, EU, US, AUS) Plastic transit case Date & time stamp In Field Adhesion Calibration Verification Mode:

-

- Technical Information

-

Technical SpecificationElcometer 510 Automatic Pull-Off Adhesion Gauge

Part Number Description Certificate F510-20S Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit

F510-20T Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit

F510-50S Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit

F510-50T Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit

Pressure Accuracy ±1% of full scale Pull Rate Accuracy ±(2.5% + 0.3 seconds) Pressure Resolution 0.01MPa (1psi) Pull Rate Resolution 0.01MPa/s (1psi/s) Dolly Diameter 10mm (0.39”) 14.2mm (0.56”) 20mm (0.76”) 50mm (1.96”) Operating Range 8 - 100MPa (1200 - 14400psi) 4 - 50MPa (600 - 7200psi) 2 - 25MPa (300 - 3600psi) 0.3 - 4MPa (50 - 580psi) Pull Rate Range 0.4 - 5.6MPa/s (58 - 812psi/s) 0.2 - 2.8MPa/s (29 - 403psi/s) 0.1 - 1.4MPa/s (15 - 203psi/s) 0.02 - 0.22MPa/s (2 - 32psi/s) Dimensions 260 x 100 x 66mm (6.3 x 3.9 x 2.6”) - Gauge Actuator Height1 85mm (3.4”) 85mm (3.4”) 85mm (3.4”) 110mm (4.3”) Instrument Weight1 2.9kg (6.4lb) 2.9kg (6.4lb) 2.9kg (6.4lb) 3.1kg (8.3lb) Kit Weight - - 6.1kg (13.5lb) 7.3kg (16.1lb) Power Supply 8 x AA batteries (16 rechargeable batteries supplied complete with charger) or AC mains power (Model T only) Battery Life ~200 pulls per charge up to 25MPa (3600psi) at 1MPa/s (150psi/s), recharge time <5 hours Packing List 20mm Kit: Elcometer 510 Adhesion Tester with 20mm dollies (x10), standard skirt for 20mm dollies, 20mm dolly cutter handle, 20mm dolly cutter, Araldite standard two part epoxy adhesive (2x 15ml tubes), abrasive pad, shoulder harness, carry case, 16x AA NiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster® Software CD & USB cable, calibration certificate and operating instructions.

50mm Kit: Elcometer 510 Adhesion Tester with 50mm dollies (x6), standard skirt for 50mm dollies, 50mm dolly cutter arbor, 50mm dolly cutter, Araldite standard two part epoxy adhesive (2x 15ml tubes), abrasive pad, shoulder harness, carry case, 16x AA NiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster® Software CD & USB cable, calibration certificate and operating instructions.Part Number Description Certificate F510-20S Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit

F510-20T Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit

F510-50S Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit

F510-50T Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit

Pressure Accuracy ±1% of full scale Pull Rate Accuracy ±(2.5% + 0.3 seconds) Pressure Resolution 0.01MPa (1psi) Pull Rate Resolution 0.01MPa/s (1psi/s) Dolly Diameter 10mm (0.39”) Operating Range 8 - 100MPa (1200 - 14400psi) Pull Rate Range 0.4 - 5.6MPa/s (58 - 812psi/s) Actuator Height1 85mm (3.4”) Instrument Weight1 2.9kg (6.4lb) Kit Weight - Dolly Diameter 14.2mm (0.56”) Operating Range 4 - 50MPa (600 - 7200psi) Pull Rate Range 0.2 - 2.8MPa/s (29 - 403psi/s) Actuator Height1 85mm (3.4”) Instrument Weight1 2.9kg (6.4lb) Kit Weight - Dolly Diameter 20mm (0.76”) Operating Range 2 - 25MPa (300 - 3600psi) Pull Rate Range 0.1 - 1.4MPa/s (15 - 203psi/s) Actuator Height1 85mm (3.4”) Instrument Weight1 2.9kg (6.4lb) Kit Weight 6.1kg (13.5lb) Dolly Diameter 50mm (1.96”) Operating Range 0.3 - 4MPa (50 - 580psi) Pull Rate Range 0.02 - 0.22MPa/s (2 - 32psi/s) Actuator Height1 110mm (4.3”) Instrument Weight1 3.1kg (8.3lb) Kit Weight 7.3kg (16.1lb) Dimensions 260 x 100 x 66mm (6.3 x 3.9 x 2.6”) - Gauge Power Supply 8 x AA batteries (16 rechargeable batteries supplied complete with charger) or AC mains power (Model T only) Battery Life ~200 pulls per charge up to 25MPa (3600psi) at 1MPa/s (150psi/s), recharge time <5 hours Packing List 20mm Kit: Elcometer 510 Adhesion Tester with 20mm dollies (x10), standard skirt for 20mm dollies, 20mm dolly cutter handle, 20mm dolly cutter, Araldite standard two part epoxy adhesive (2x 15ml tubes), abrasive pad, shoulder harness, carry case, 16x AA NiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster® Software CD & USB cable, calibration certificate and operating instructions.

50mm Kit: Elcometer 510 Adhesion Tester with 50mm dollies (x6), standard skirt for 50mm dollies, 50mm dolly cutter arbor, 50mm dolly cutter, Araldite standard two part epoxy adhesive (2x 15ml tubes), abrasive pad, shoulder harness, carry case, 16x AA NiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster® Software CD & USB cable, calibration certificate and operating instructions.● Calibration Certificate supplied as standard

1 Including Actuator with Standard Skirt fitted.- Standards

-

StandardsElcometer 510 Automatic Pull-Off Adhesion Gauge

ASTM C1583, ASTM D4541, ASTM D7234-12, AS/NZS 1580.408.5, BS 1881-207, DIN 1048-2, EN 1015-12, EN 12636, EN 13144, EN 1542, EN 24624, ISO 16276-1, ISO 4624, JIS K 5600 5-7, NF T30-606, NF T30-062

Standards in grey have been superseded but are still recognised in some industries.

- Downloads

-

Downloads

-

Elcometer 510 Automatic Pull-Off Adhesion Gauge Model T Multi-Lingual Instruction Manual

-

Elcometer 510 Automatic Pull-Off Adhesion Gauge Model S Multi-Lingual Instruction Manual

-

Elcometer 510 Automatic Pull-Off Adhesion Tester Datasheet

-

Elcometer 510 Model S Automatic Pull-Off Adhesion Gauge Declaration of Conformity

-

Elcometer 510 Model T Automatic Pull-Off Adhesion Gauge Declaration of Conformity

-

Elcometer 510 Model T Automatic Pull-Off Adhesion Gauge UKCA Declaration of Conformity

-

Elcometer 510 Model S Automatic Pull-Off Adhesion Gauge UKCA Declaration of Conformity

-

Araldite Standard Ultra Hardener Safety Data Sheet

-

Araldite Standard Ultra Resin Safety Data Sheet

- Part Numbers

-

Part NumbersElcometer 510 Automatic Pull-Off Adhesion GaugeNo data found!!

-

Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit

Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit- Model: Model S

- Dolly Diameter: 10mm (0.39”), 14.2mm (0.56”), 20mm (0.76”)

- Part Number : F510-20S

-

Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit

Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit- Model: Model T

- Dolly Diameter: 10mm (0.39”), 14.2mm (0.56”), 20mm (0.76”)

- Part Number : F510-20T

-

Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit

Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit- Model: Model S

- Dolly Diameter: 50mm (1.96”)

- Part Number : F510-50S

-

Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit

Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit- Model: Model T

- Dolly Diameter: 50mm (1.96”)

- Part Number : F510-50T

- Accessories

-

AccessoriesElcometer 510 Automatic Pull-Off Adhesion Gauge

Part Number: T99923797

Part Number: T99923797 Part Number: T99912906

Part Number: T99912906 Part Number: T99923147

Part Number: T99923147 Part Number: T99923103

Part Number: T99923103 Part Number: T5100010AL-10

Part Number: T5100010AL-10 Part Number: T9990014AL-10

Part Number: T9990014AL-10 Part Number: T9990020AL-10

Part Number: T9990020AL-10 Part Number: T9990050AL-4

Part Number: T9990050AL-4 Part Number: T9990050SS-4

Part Number: T9990050SS-4 Part Number: T5100010AL-100

Part Number: T5100010AL-100 Part Number: T9990014AL-100

Part Number: T9990014AL-100 Part Number: T9990020AL-100

Part Number: T9990020AL-100 Part Number: T9991420S

Part Number: T9991420S Part Number: T9990050S

Part Number: T9990050S Part Number: T9990014T

Part Number: T9990014T Part Number: T9990020T

Part Number: T9990020T Part Number: T9991420H

Part Number: T9991420H Part Number: T9990050H

Part Number: T9990050H Part Number: T9990014CT

Part Number: T9990014CT Part Number: T9990020CT

Part Number: T9990020CT Part Number: T9990050CT

Part Number: T9990050CT

Welcome to Elcometer.tv

Your ultimate training channel

- Home

- Coatings Inspection

- Coatings Inspection Division

- Adhesion Testers

- Elcometer 510 Automatic Pull-Off Adhesion Gauge

Elcometer 510 Automatic Pull-Off Adhesion Gauge

- Protective Coatings

- Industrial Finishing

The Elcometer 510 Automatic Pull-Off Adhesion Gauge accurately measures the adhesion strength of coatings on a wide range of substrates.

Accurate Pull-Off Measurements

- Fully adjustable pull rates 0.1-1.4MPa/s (14.5-203psi)

- Accuracy of ±1% of full scale

- Can be used in accordance with National & International Standards

- Interchangeable units: MPa, psi, Nmm² and N

Powerful Adhesion Tester

- Smooth load application up to 100MPa (14,400psi)

- USB and Bluetooth® data output to iOS or Android™ devices

- Stores up to 60,000 readings in 2,500 batches

Efficient Adhesion Testing

- Ideal for laboratory and field use

- 10, 14.2, 20 & 50mm (0.39, 0.56, 0.76 & 1.96”) diameter reusable dollies

- Compatible with ElcoMaster® Software

- Range of substrate actuator skirts for thick, thin, flat or convex substrates

Summary

Elcometer 510 Automatic Pull-Off Adhesion Gauge

Using an automatic hydraulic pump, the Elcometer 510 Pull-Off Adhesion Tester ensures smooth and continuous pressure application for consistent and repeatable results. Whilst the rate of pull is controlled manually for most pull-off adhesion testers, the Elcometer 510 Pull-Off Adhesion Gauge allows the rate of pull to be selected, and the gauge applies the pre-selected rate automatically.

The Elcometer 510 Pull-Off Adhesion Tester includes all the features that you have come to expect from an Elcometer designed and manufactured product, including ease of use, robust and ergonomic design, menu driven colour display, user selectable statistics and display modes.

As well as reducing inspection times, the Elcometer 510 Pull-Off Adhesion Gauge can also speed up inspection reporting. When out in the field or on site, users can instantly review their data using Elcometer’s free data management software, ElcoMaster®. Each live reading can be transferred via Bluetooth® to a PC, or mobile devices and, at the click of a button, users are able to generate professional reports.

Downloads-

Elcometer 510 Automatic Pull-Off Adhesion Gauge Model T Multi-Lingual Instruction Manual

-

Elcometer 510 Automatic Pull-Off Adhesion Gauge Model S Multi-Lingual Instruction Manual

-

Elcometer 510 Automatic Pull-Off Adhesion Tester Datasheet

-

Elcometer 510 Model S Automatic Pull-Off Adhesion Gauge Declaration of Conformity

-

Elcometer 510 Model T Automatic Pull-Off Adhesion Gauge Declaration of Conformity

-

Elcometer 510 Model T Automatic Pull-Off Adhesion Gauge UKCA Declaration of Conformity

-

Elcometer 510 Model S Automatic Pull-Off Adhesion Gauge UKCA Declaration of Conformity

-

Araldite Standard Ultra Hardener Safety Data Sheet

-

Araldite Standard Ultra Resin Safety Data Sheet

Key Features

Elcometer 510 Automatic Pull-Off Adhesion Gauge

Durability That Lasts

- Sealed, heavy duty and impact resistant

- Dust and waterproof equivalent to IP64

- Suitable for use in harsh environments

An Adhesion Gauge You Can Trust

- Repeatable and reproducible pull off measurements

- 2 year gauge warranty

- Batch date and time stamp facility

Adhesion Tests Made Simple

- Supplied in a robust plastic carry case for easy transportation

- USB and Bluetooth® data output to iPhone or Android™ devices

- Bright LCD colour screen

Elcometer 510 Automatic Pull-Off Adhesion Gauge Features Explained:

Automatic adhesion tester with selectable pull rates for 10, 14.2, 20 & 50mm diameter dollies. View adhesion trend graphs or live statistics alongside the reading value.

View adhesion trend graphs or live statistics alongside the reading value. Individual user-definable adhesion pull rate graphs can be saved with each reading.

Individual user-definable adhesion pull rate graphs can be saved with each reading. Stores individual adhesion strength readings and pull rate graphs in up to 2,500 alpha numeric batches, together with date, time and attribute information.

Stores individual adhesion strength readings and pull rate graphs in up to 2,500 alpha numeric batches, together with date, time and attribute information. Either pull to maximum or pull to preset limit. Unique time hold feature allows users to set a delay before pressure returns to zero.

Either pull to maximum or pull to preset limit. Unique time hold feature allows users to set a delay before pressure returns to zero. Save cohesive and adhesive failure attributes alongside your adhesion pull data in accordance with National and International Standards.Product FeaturesElcometer 510 Automatic Pull-Off Adhesion Gauge

Save cohesive and adhesive failure attributes alongside your adhesion pull data in accordance with National and International Standards.Product FeaturesElcometer 510 Automatic Pull-Off Adhesion GaugeModel S Model T Repeatable & reproducible measurements Easy to use menu structure in multiple languages Tough, impact, waterproof & dust resistant; equivalent to IP64 Bright LCD colour screen; with ambient light sensor Scratch & solvent resistant display; 2.4” (6cm) TFT Calibration certificate 2 year gauge warranty1 Automatic rotating display; 0°, 180° Data output via USB (Live readings - and batch) Data output via Bluetooth® PC command; start & stop gauge from a PC with live readings (USB only) Switchable Units (MPa, psi, N, Nmm-2) On Screen Statistics (η, x, σ, Hi, Lo, CV%, N>hi limit2) Pull Rate Indicator Trend Graph Pull Rate Graph (Load v Time) Interchangeable Dolly Selection; 10, 14.2, 20 & 50mm User Selectable Pull Rates; (Model S & Model T Standard Mode) 10mm: 1.00, 2.00, 3.00, 4.00, 5.00MPa/s 125, 200, 400, 600, 725psi/s 14.2mm: 0.4, 0.7, 1.4, 2.0, 2.5MPa/s 60, 100, 200, 300, 360psi/s 20mm: 0.2, 0.3, 0.7, 1.0, 1.2MPa/s 30, 50, 100, 150, 180psi/s 50mm: 0.04, 0.08, 0.12, 0.16, 0.20MPa/s 5, 8, 16, 24, 30psi/s User Selectable Pull Rates; (Model T Advanced Mode) 10mm: 0.40 - 5.60MPa/s 58 - 812psi/s in 0.1MPa / 1psi steps 14.2mm: 0.20 - 2.80MPa/s 29 - 403psi/s in 0.1MPa / 1psi steps 20mm: 0.10 - 1.40MPa/s 15 - 203psi/s in 0.1MPa / 1psi steps 50mm: 0.02 - 0.22MPa/s 2 - 32psi/s in 0.01MPa / 0.1psi steps User Selectable Limit & Limit Hold Time Gauge Memory; maximum number of readings 6060,0003Number of Batches (Alpha Numeric - Model T) 12,500Attribute Modes to meet National & International Standards Display Modes Readings, Selected Stats & Run Chart (last 20 readings) Pull Rate Graphs Batch Review Power; Battery (B), AC Mains Power (M) BB, MUSB Cable & ElcoMaster® Software CD Power Cable with Multi International Plug Adaptor (UK, EU, US, AUS) Plastic transit case Date & time stamp In Field Adhesion Calibration Verification Mode: Technical SpecificationElcometer 510 Automatic Pull-Off Adhesion GaugePart Number Description Certificate F510-20S Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit

F510-20T Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit

F510-50S Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit

F510-50T Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit

Pressure Accuracy ±1% of full scale Pull Rate Accuracy ±(2.5% + 0.3 seconds) Pressure Resolution 0.01MPa (1psi) Pull Rate Resolution 0.01MPa/s (1psi/s) Dolly Diameter 10mm (0.39”) 14.2mm (0.56”) 20mm (0.76”) 50mm (1.96”) Operating Range 8 - 100MPa (1200 - 14400psi) 4 - 50MPa (600 - 7200psi) 2 - 25MPa (300 - 3600psi) 0.3 - 4MPa (50 - 580psi) Pull Rate Range 0.4 - 5.6MPa/s (58 - 812psi/s) 0.2 - 2.8MPa/s (29 - 403psi/s) 0.1 - 1.4MPa/s (15 - 203psi/s) 0.02 - 0.22MPa/s (2 - 32psi/s) Dimensions 260 x 100 x 66mm (6.3 x 3.9 x 2.6”) - Gauge Actuator Height1 85mm (3.4”) 85mm (3.4”) 85mm (3.4”) 110mm (4.3”) Instrument Weight1 2.9kg (6.4lb) 2.9kg (6.4lb) 2.9kg (6.4lb) 3.1kg (8.3lb) Kit Weight - - 6.1kg (13.5lb) 7.3kg (16.1lb) Power Supply 8 x AA batteries (16 rechargeable batteries supplied complete with charger) or AC mains power (Model T only) Battery Life ~200 pulls per charge up to 25MPa (3600psi) at 1MPa/s (150psi/s), recharge time <5 hours Packing List 20mm Kit: Elcometer 510 Adhesion Tester with 20mm dollies (x10), standard skirt for 20mm dollies, 20mm dolly cutter handle, 20mm dolly cutter, Araldite standard two part epoxy adhesive (2x 15ml tubes), abrasive pad, shoulder harness, carry case, 16x AA NiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster® Software CD & USB cable, calibration certificate and operating instructions.

50mm Kit: Elcometer 510 Adhesion Tester with 50mm dollies (x6), standard skirt for 50mm dollies, 50mm dolly cutter arbor, 50mm dolly cutter, Araldite standard two part epoxy adhesive (2x 15ml tubes), abrasive pad, shoulder harness, carry case, 16x AA NiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster® Software CD & USB cable, calibration certificate and operating instructions.Part Number Description Certificate F510-20S Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit

F510-20T Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit

F510-50S Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit

F510-50T Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit

Pressure Accuracy ±1% of full scale Pull Rate Accuracy ±(2.5% + 0.3 seconds) Pressure Resolution 0.01MPa (1psi) Pull Rate Resolution 0.01MPa/s (1psi/s) Dolly Diameter 10mm (0.39”) Operating Range 8 - 100MPa (1200 - 14400psi) Pull Rate Range 0.4 - 5.6MPa/s (58 - 812psi/s) Actuator Height1 85mm (3.4”) Instrument Weight1 2.9kg (6.4lb) Kit Weight - Dolly Diameter 14.2mm (0.56”) Operating Range 4 - 50MPa (600 - 7200psi) Pull Rate Range 0.2 - 2.8MPa/s (29 - 403psi/s) Actuator Height1 85mm (3.4”) Instrument Weight1 2.9kg (6.4lb) Kit Weight - Dolly Diameter 20mm (0.76”) Operating Range 2 - 25MPa (300 - 3600psi) Pull Rate Range 0.1 - 1.4MPa/s (15 - 203psi/s) Actuator Height1 85mm (3.4”) Instrument Weight1 2.9kg (6.4lb) Kit Weight 6.1kg (13.5lb) Dolly Diameter 50mm (1.96”) Operating Range 0.3 - 4MPa (50 - 580psi) Pull Rate Range 0.02 - 0.22MPa/s (2 - 32psi/s) Actuator Height1 110mm (4.3”) Instrument Weight1 3.1kg (8.3lb) Kit Weight 7.3kg (16.1lb) Dimensions 260 x 100 x 66mm (6.3 x 3.9 x 2.6”) - Gauge Power Supply 8 x AA batteries (16 rechargeable batteries supplied complete with charger) or AC mains power (Model T only) Battery Life ~200 pulls per charge up to 25MPa (3600psi) at 1MPa/s (150psi/s), recharge time <5 hours Packing List 20mm Kit: Elcometer 510 Adhesion Tester with 20mm dollies (x10), standard skirt for 20mm dollies, 20mm dolly cutter handle, 20mm dolly cutter, Araldite standard two part epoxy adhesive (2x 15ml tubes), abrasive pad, shoulder harness, carry case, 16x AA NiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster® Software CD & USB cable, calibration certificate and operating instructions.

50mm Kit: Elcometer 510 Adhesion Tester with 50mm dollies (x6), standard skirt for 50mm dollies, 50mm dolly cutter arbor, 50mm dolly cutter, Araldite standard two part epoxy adhesive (2x 15ml tubes), abrasive pad, shoulder harness, carry case, 16x AA NiMH rechargeable batteries & charger (UK, EU, US, AUS), mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster® Software CD & USB cable, calibration certificate and operating instructions.● Calibration Certificate supplied as standard

1 Including Actuator with Standard Skirt fitted.StandardsElcometer 510 Automatic Pull-Off Adhesion GaugeASTM C1583, ASTM D4541, ASTM D7234-12, AS/NZS 1580.408.5, BS 1881-207, DIN 1048-2, EN 1015-12, EN 12636, EN 13144, EN 1542, EN 24624, ISO 16276-1, ISO 4624, JIS K 5600 5-7, NF T30-606, NF T30-062

Standards in grey have been superseded but are still recognised in some industries.

Part NumbersElcometer 510 Automatic Pull-Off Adhesion GaugeNo data found!!-

Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit

Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit- Model: Model S

- Dolly Diameter: 10mm (0.39”), 14.2mm (0.56”), 20mm (0.76”)

- Part Number : F510-20S

-

Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit

Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit- Model: Model T

- Dolly Diameter: 10mm (0.39”), 14.2mm (0.56”), 20mm (0.76”)

- Part Number : F510-20T

-

Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit

Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit- Model: Model S

- Dolly Diameter: 50mm (1.96”)

- Part Number : F510-50S

-

Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit

Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit- Model: Model T

- Dolly Diameter: 50mm (1.96”)

- Part Number : F510-50T

Welcome to Elcometer.tv

Your ultimate training channelAccessoriesElcometer 510 Automatic Pull-Off Adhesion Gauge Part Number: T99923797

Part Number: T99923797 Part Number: T99912906

Part Number: T99912906 Part Number: T99923147

Part Number: T99923147 Part Number: T99923103

Part Number: T99923103 Part Number: T5100010AL-10

Part Number: T5100010AL-10 Part Number: T9990014AL-10

Part Number: T9990014AL-10 Part Number: T9990020AL-10

Part Number: T9990020AL-10 Part Number: T9990050AL-4

Part Number: T9990050AL-4 Part Number: T9990050SS-4

Part Number: T9990050SS-4 Part Number: T5100010AL-100

Part Number: T5100010AL-100 Part Number: T9990014AL-100

Part Number: T9990014AL-100 Part Number: T9990020AL-100

Part Number: T9990020AL-100 Part Number: T9991420S

Part Number: T9991420S Part Number: T9990050S

Part Number: T9990050S Part Number: T9990014T

Part Number: T9990014T Part Number: T9990020T

Part Number: T9990020T Part Number: T9991420H

Part Number: T9991420H Part Number: T9990050H

Part Number: T9990050H Part Number: T9990014CT

Part Number: T9990014CT Part Number: T9990020CT

Part Number: T9990020CT Part Number: T9990050CT

Part Number: T9990050CT

-

- Standards

-