For over seventy years, Elcometer has been a world leader in the design, manufacture and supply of inspection equipment to the coatings industry.

Whether you are measuring surface profile, surface cleanliness, dry film thickness, porosity, adhesion or gloss; or testing the abrasion, scratch resistance or elasticity of a coating - Elcometer's extensive and versatile range of equipment provides the complete solution to your coatings inspection requirements, whatever and wherever they might be.

For over seventy years, Elcometer has been a world leader in the design, manufacture and supply of inspection equipment to the coatings industry.

Whether you are measuring surface profile, surface cleanliness, dry film thickness, porosity, adhesion or gloss; or testing the abrasion, scratch resistance or elasticity of a coating - Elcometer's extensive and versatile range of equipment provides the complete solution to your coatings inspection requirements, whatever and wherever they might be.

-

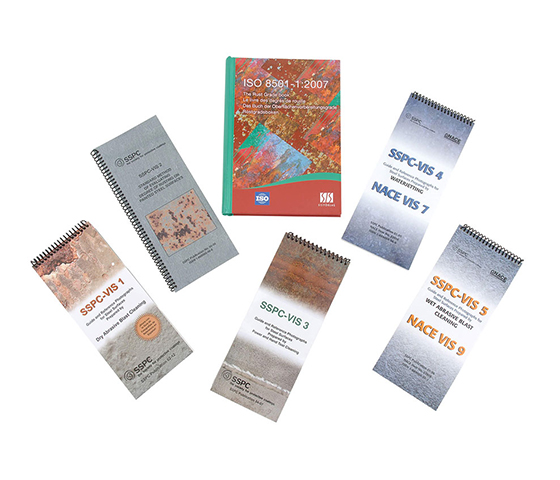

A range of products designed to quickly and accurately assess surface cleanliness before application of coating.

-

A range of instruments designed to measure climatic conditions during the coating process.

-

A comprehensive range of Dry Film Thickness, Coating Thickness and Paint Gauges to meet all of your coating inspection requirements.

-

ElcoMaster® is a fast, easy to use software and mobile app for all your data management, analysis and reporting needs.

-

A range of products used to monitor and control important parameters during the blasting process.

-

A range of products used to assess the condition of a surface, including visual comparators and weld gauges.

-

A range of digital and mechanical surface profile gauges and surface comparators for measuring surface profile.

-

A light and portable gauge used to measure surface roughness in accordance with International Standards.

-

Digital moisture meters both pin-type and contact-type to establish the moisture content.

-

Easy to use oven temperature profile solution for a quality finish and a successful cure of a powder coating.

-

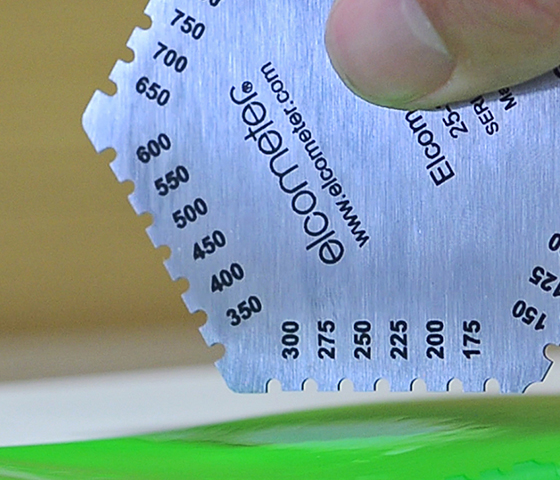

A range of products for measuring uncured wet film thickness and powder thickness for high quality finish and minimal waste.

-

Adhesion testers are used to verify that both surface preparation and coating application are within specification.

-

A range of fast and easy to use ultrasonic material thickness gauges, ideal for measuring the thickness of metals, plastics, glass, epoxies and ceramics.

-

Ideal for measuring and recording material thickness from just 0.15mm (0.006”) to 500mm (20”) and sound velocity on a variety of substrates.

-

A range of versatile pinhole & porosity detectors designed to meet the most exacting specifications.

-

A range of accessories to support your coating inspection, from inspection mirrors to publications.

-

Elcometer offer one of the widest ranges of inspection equipment available from digital inspection to surface contamination kits.

-

A range of glossmeters used to measure gloss and reflectance on a wide range of surfaces from high gloss to matt.

-

A material’s ability to absorb certain wavelengths of light and reflect others is defined as its colour.

-

A comprehensive range of fineness of grind gauges used to determine the particle size and fineness of grind of many materials.

-

A range of cups and laboratory balances for accurate measurements during the development of a coating.

-

A range of viscosity cups from flow to dip cups for quick assessment of material viscosity to suit specific standards.

-

Elcometer offer a range of flash point testing equipment, including open cup and closed cup testers.

-

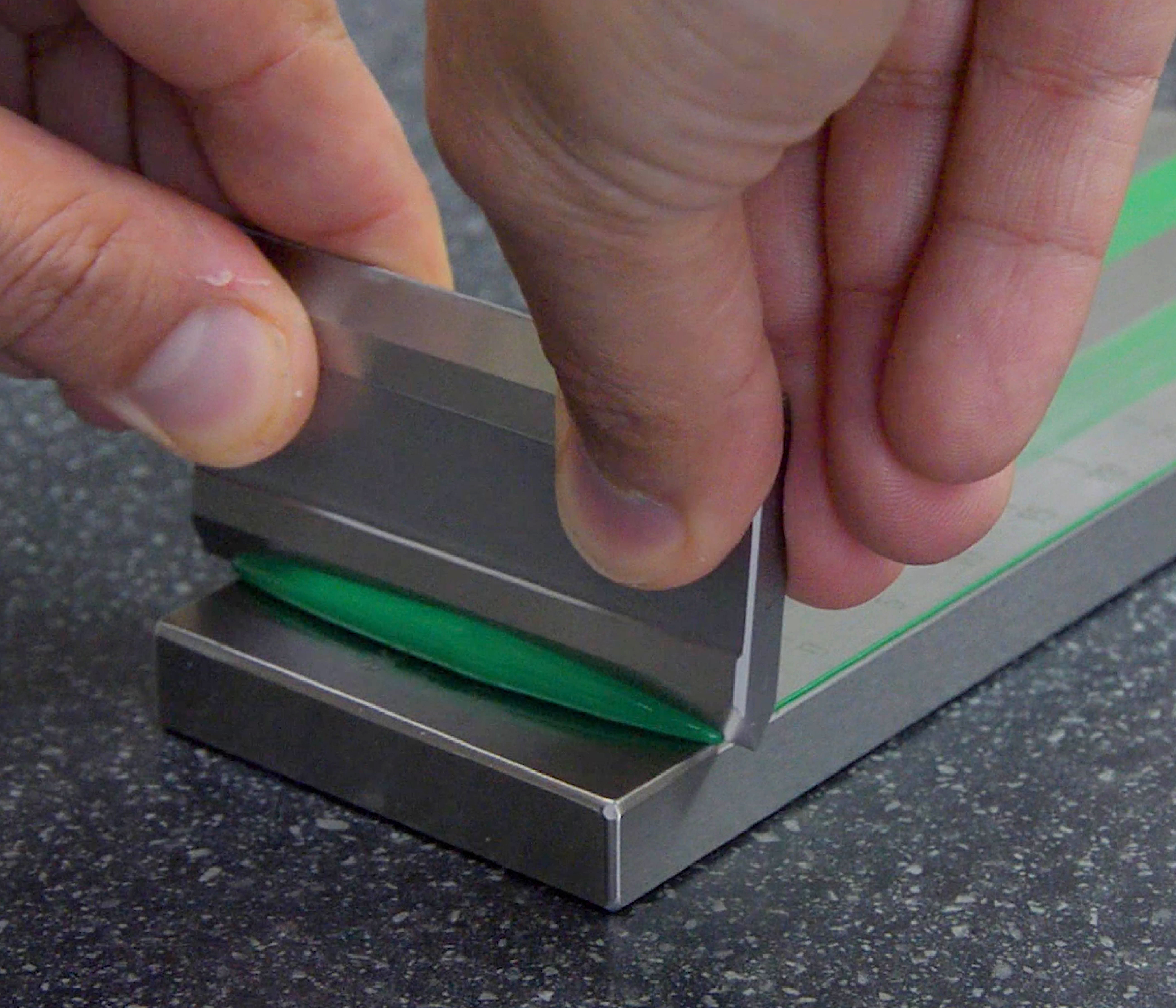

A range of high precision film applicators and spiral bar coaters essential for preparing a wide variety of product samples.

-

A range designed to determine a coating's drying time and a material’s degree of permeability or permeance.

-

A range of versatile instruments for testing washability, brushability and resistance of a wide range of materials.

-

A range of motorised and manual testers to determine a material’s resistance to scratch, wear and indentation.

-

A range of mechanical instruments for repeatable and reproducible bend, cupping and impact tests.